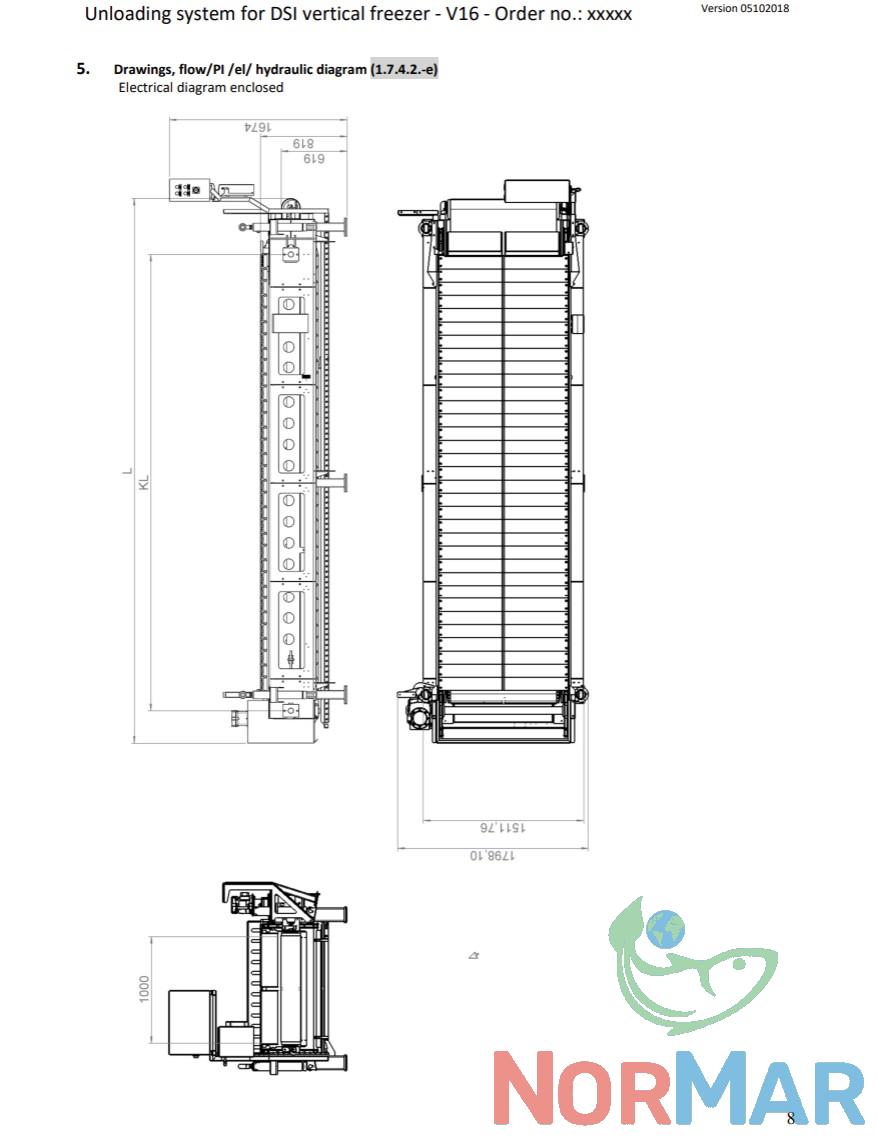

Description

DSI V16 30-100 Vertical plate freezer

With base for automatic emptying of the plate freezer

Production: 03/2020

Condition: Good, operational

Has been in use for approx. 2.5 years

Was taken out in connection with the installation of new equipment at the factory that required more space.

The plate freezer is stored dry and well.

DSI V16 30-100 is a block freezer with automatic unloading, designed to freeze blocks up to 1000x500x100 mm. This includes a variety of products, from whole fish to liquid-based items. The machine is developed in collaboration with Dybvad Stål Industri A/S.

Designed for Efficient Freezing

This freezer is built for quick freezing of food and food-related products that do not react with aluminum. Any other use should only be considered after consulting the manufacturer.

The DSI V16 30-100 consists of multiple compartments, with vertical freezing elements acting as dividers. The distance between these elements is controlled by distance profiles. Each freezing station can be further divided into smaller sections using vertical separator plates.

How It Works

The freezing elements move sideways to open and close the stations, while the top part moves vertically to lift the frozen blocks out. These functions are powered by a hydraulic system, controlled via the main panel.

The freezing process follows these steps:

- The stations close and are filled with the product.

- Refrigeration starts, freezing the contents over a set period.

- Once freezing is complete, the defrosting system activates.

- The upper section lifts, releasing the frozen blocks.

- The blocks are transported out via the lower conveyor belt.

- After cleaning, the process repeats.

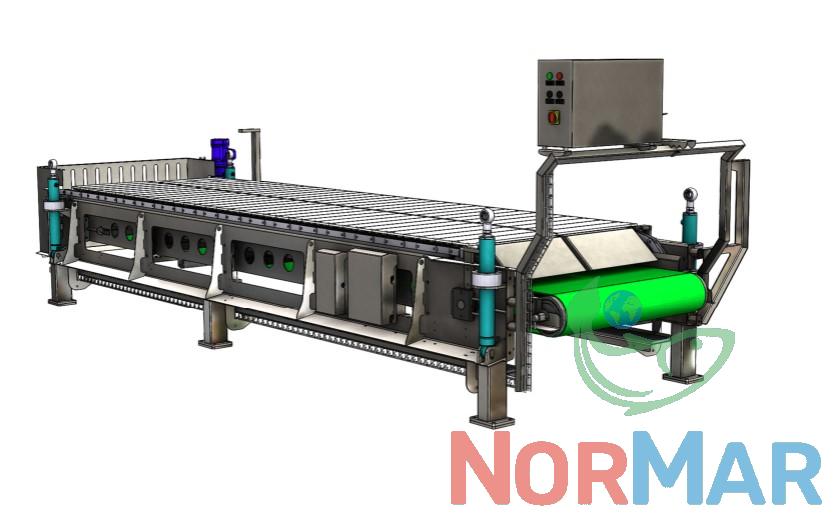

Base Structure and Transport System

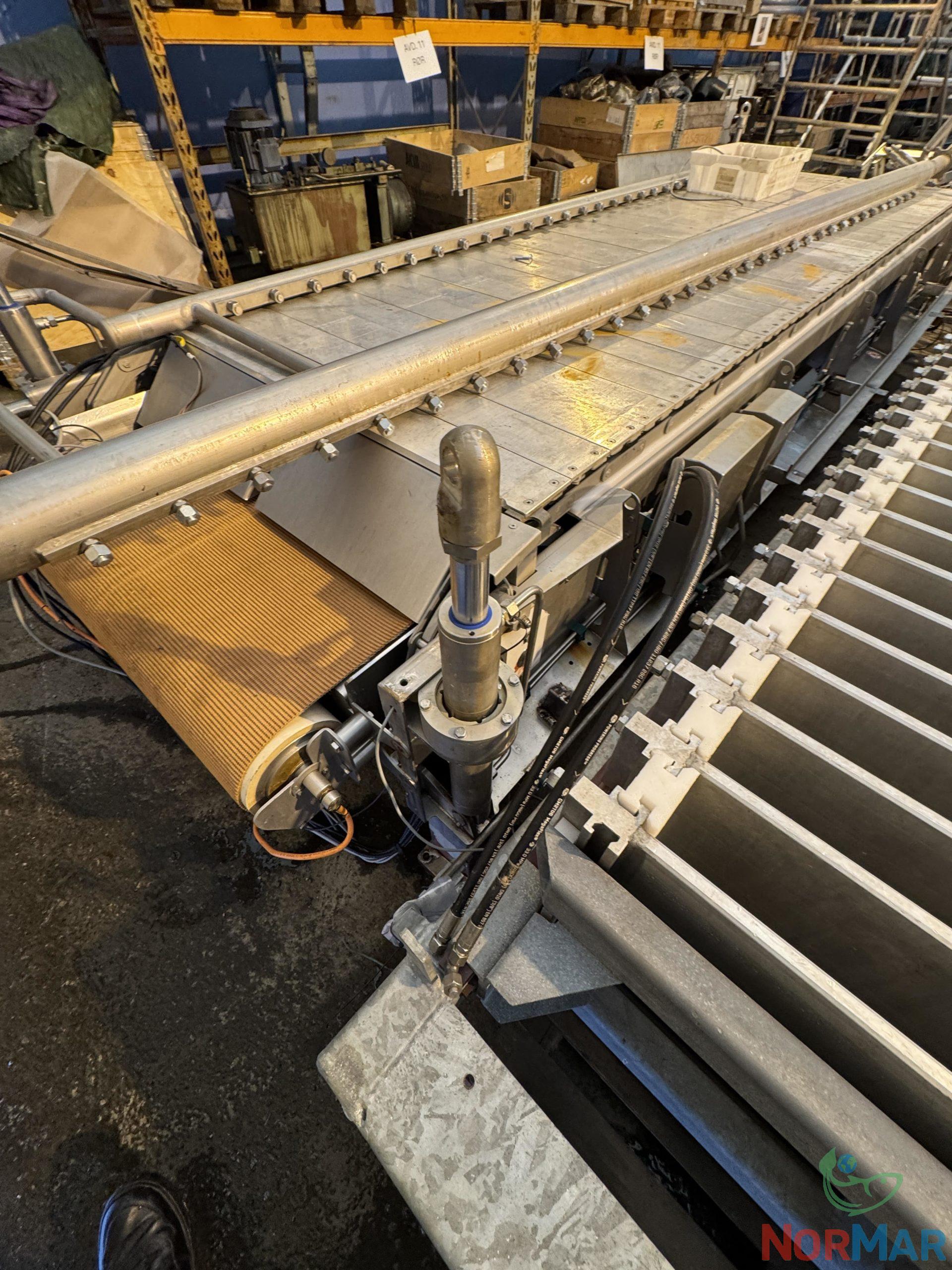

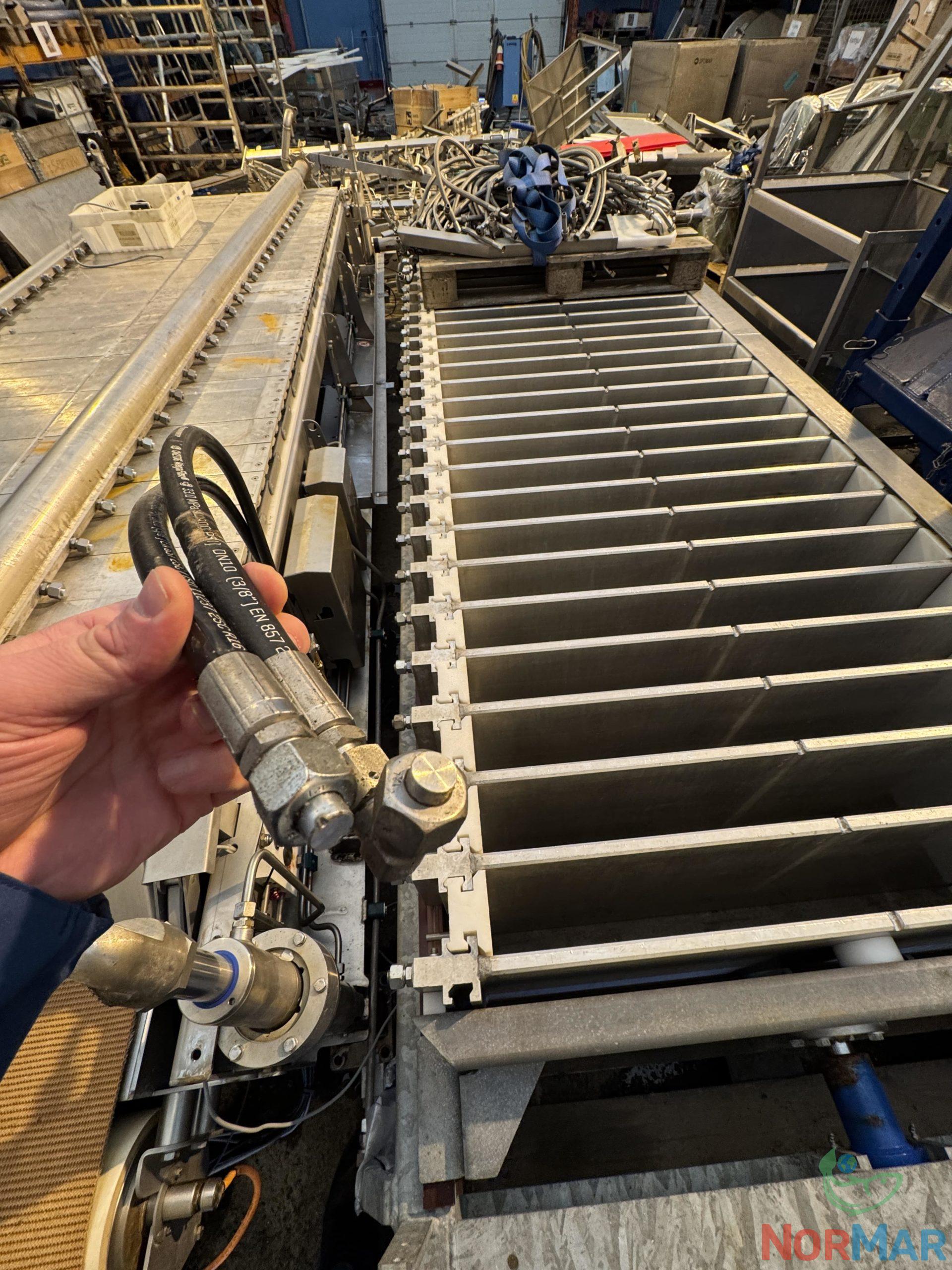

The V16 base part consists of a sturdy frame that supports two conveyors. These conveyors are arranged in a way that ensures smooth transport of the frozen blocks.

The outer conveyor is made of aluminum fins, mounted on approximately 35% of the conveyor chains. These fins form a flat surface, supporting the frozen blocks as they exit. The movement is controlled by a hydraulic gear motor.

After freezing, and once the upper section is lifted, the chain conveyor starts moving. It gradually pulls the bottom section away, allowing the blocks to slide out. The blocks are then transported via a conveyor belt, typically leading to a packing station.

To optimize efficiency, the chain conveyor runs only as long as needed to unload all blocks. Once complete, it reverses direction and moves swiftly back to its starting position, ready for the next cycle.

Specifications:

Block thickness: 100 mm

Number of stations: 30

Plate size (L×W): 1000×500 mm

The refrigerants approved for use in this freezer, usually R22, NH3, or CO2