Description

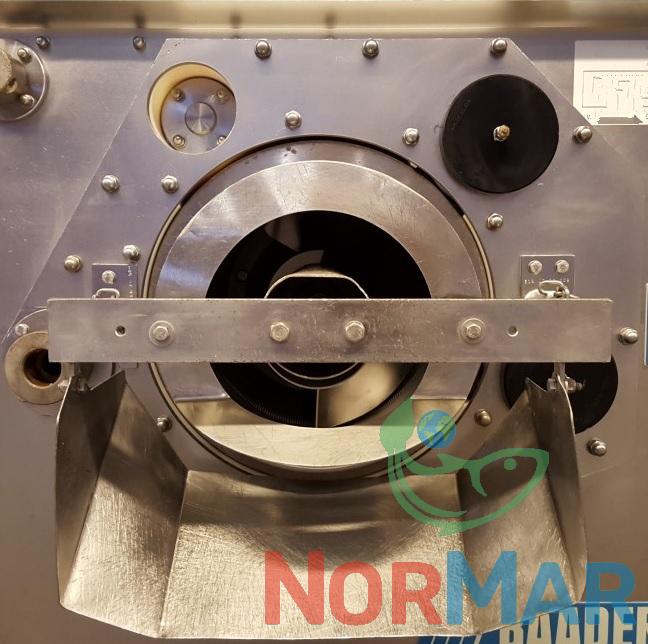

Baader 605 bone separator is designed to delicately separate meat from waste components such as bones, veins, and skin. It is capable of processing various types of products, including fish, deboned turkey drumsticks, chicken backs, legs, wings, tails, necks, turkey and chicken carcasses.

During the separation process, the solid components remain outside the drum, while the soft components are pressed through the holes of the perforated drum. The ratio between yield and quality can be adjusted by controlling the pressure roller.

The operation of the bone separator machine involves a flexible squeezing belt that feeds the product to the perforated drum and applies pressure to press the soft components through the holes, separating them from the solid components.

Capacity of Baader 605 bone separator model: Up to 3500 kg per hour.

Voltage: 3 x 400 V.

Hole diameter: Available in 2 mm or 5 mm options.

Operator: Requires 1 person to operate the machine.