Fish processing solutions comprise a complex network of systems, production lines, and conveyors widely utilized in the fish processing industry to optimize internal processes.

Since 1998 in the fish market, NorMar has the experience, competence, and partnerships to deliver systems tailored to the needs of our customers.

Contact us for expert consultations and competitive offers on fish processing solutions, ensuring the optimization of your seafood processing operations

Showing all 16 results

We specialize in providing a comprehensive suite of fish processing machines and solutions, designed to meet the varied needs of our clients. Our portfolio includes options for manual gutting and trimmings lines, as well as bulk feeders, conveyors, and additional equipment. We take great pride in customizing our fish processing solutions to match the exact requirements of our customers. We want to be sure their operations are both efficient and optimized. Our range is geared towards enhancing every aspect of the fish processing workflow, from precision in manual tasks to the integration of automated technologies.

Bulk feeders are specialized automated systems used to handle and distribute large quantities of products within processing lines. These feeders play a crucial role in streamlining the processing workflow by ensuring a continuous and uniform flow of raw materials.

Bulk feeders in fish processing typically consist of conveyor systems for efficient transport fish between stages. They can handle various sizes and types of fish, accommodating the diverse needs of seafood processing facilities.

A manual gutting line in fish processing is a dedicated system designed for the hands-on removal of internal organs from fish. Comprising a conveyor system, workers stationed along the line manually perform the gutting process using knives and gutting boards. This system is adaptable to handle various fish sizes and species, offering flexibility in processing different types of seafood. To ensure hygiene and cleanliness, some manual gutting lines incorporate water jets or vacuum systems to remove waste and residue.

A manual trimming line in fish processing is a specialized system tailored for the meticulous trimming of fish fillets. Featuring a conveyor system, this line guides fish fillets through designated workstations where workers manually perform precise trimming using tools such as knives and trimming boards. The line is adjustable to accommodate various sizes and types of fish fillets, offering flexibility in processing different seafood products.

Workers on the line play a critical role in quality control. They ensuring that each fish fillet meets the desired standards by visually inspecting and precisely trimming away any unwanted parts. In certain setups, manual trimming lines may include water jets or vacuum systems to uphold cleanliness standards. The adaptability and attention to detail make manual trimming lines valuable. Particularly when dealing with fish fillets that require a hands-on approach for precision trimming. While automated systems are prevalent in modern fish processing, manual trimming lines provide a level of customization essential for specific processing needs.

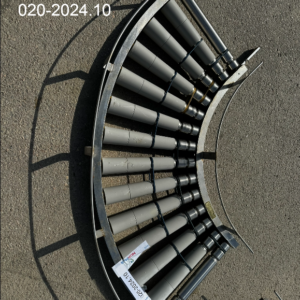

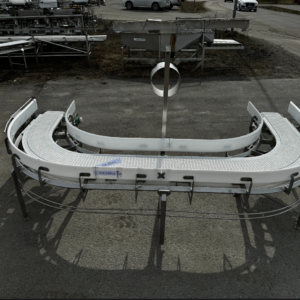

Conveyors play a pivotal role in the seamless transportation of fish products within a processing facility, efficiently moving them from one stage to another. These essential systems are designed to streamline the workflow by ensuring a continuous and controlled transfer of fish products along the processing line.

Tailored to the diverse needs of customers, conveyors can be built in different sizes to accommodate varying production requirements. Their versatility allows for the transportation of fish products of different shapes, sizes, and weights. They can be adapted to the specific demands of the seafood processing industry.

These conveyor systems contribute significantly to the optimization of processing operations, enhancing efficiency and reducing manual handling. Whether conveying whole fish, fillets, or other seafood products, conveyors are a fundamental component in modern fish processing facilities. They providing a reliable and customizable solution to meet the unique requirements of each stage in the production line.